Kechen Panel (Cleanroom Panel) - 50mm

Cleanroom panels are versatile materials made from materials like rock wool, PU foam, and paper honeycomb, each with its unique advantages and characteristics. Therefore, choosing the cleanroom panels that suit your needs can provide a safe, efficient, and cost-effective solution.

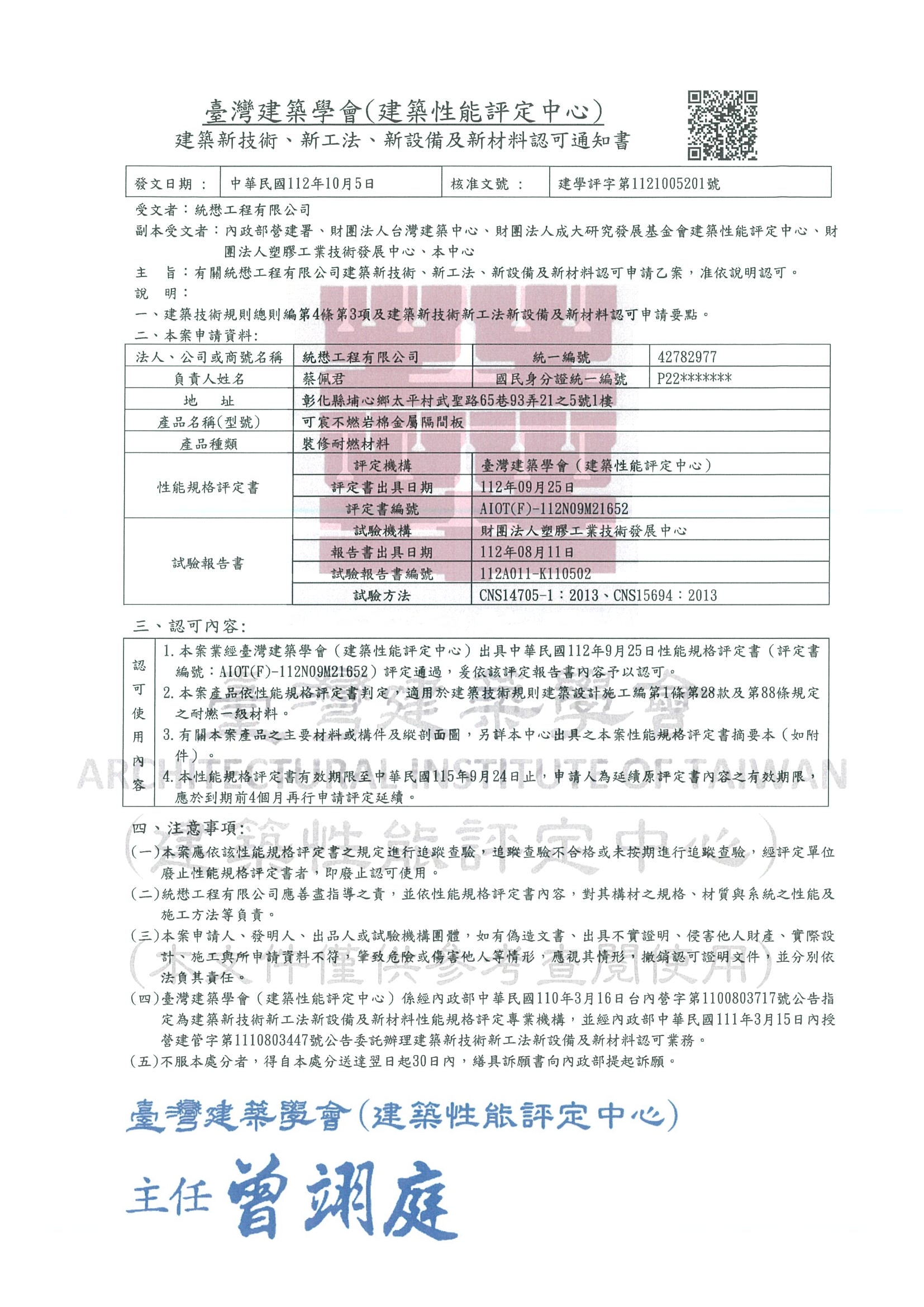

One of the primary types of cleanroom panels, cleanroom rock wool panels, is a partition material primarily made from mineral wool combined with a small amount of binding agents and fire retardants. The lightweight nature of the core material makes it easy to install and transport. It not only possesses excellent thermal insulation and sound-absorbing properties but also offers advantages such as fire resistance, moisture resistance, corrosion resistance, and environmental friendliness. It is the ideal choice when planning fire-resistant areas within your facility.

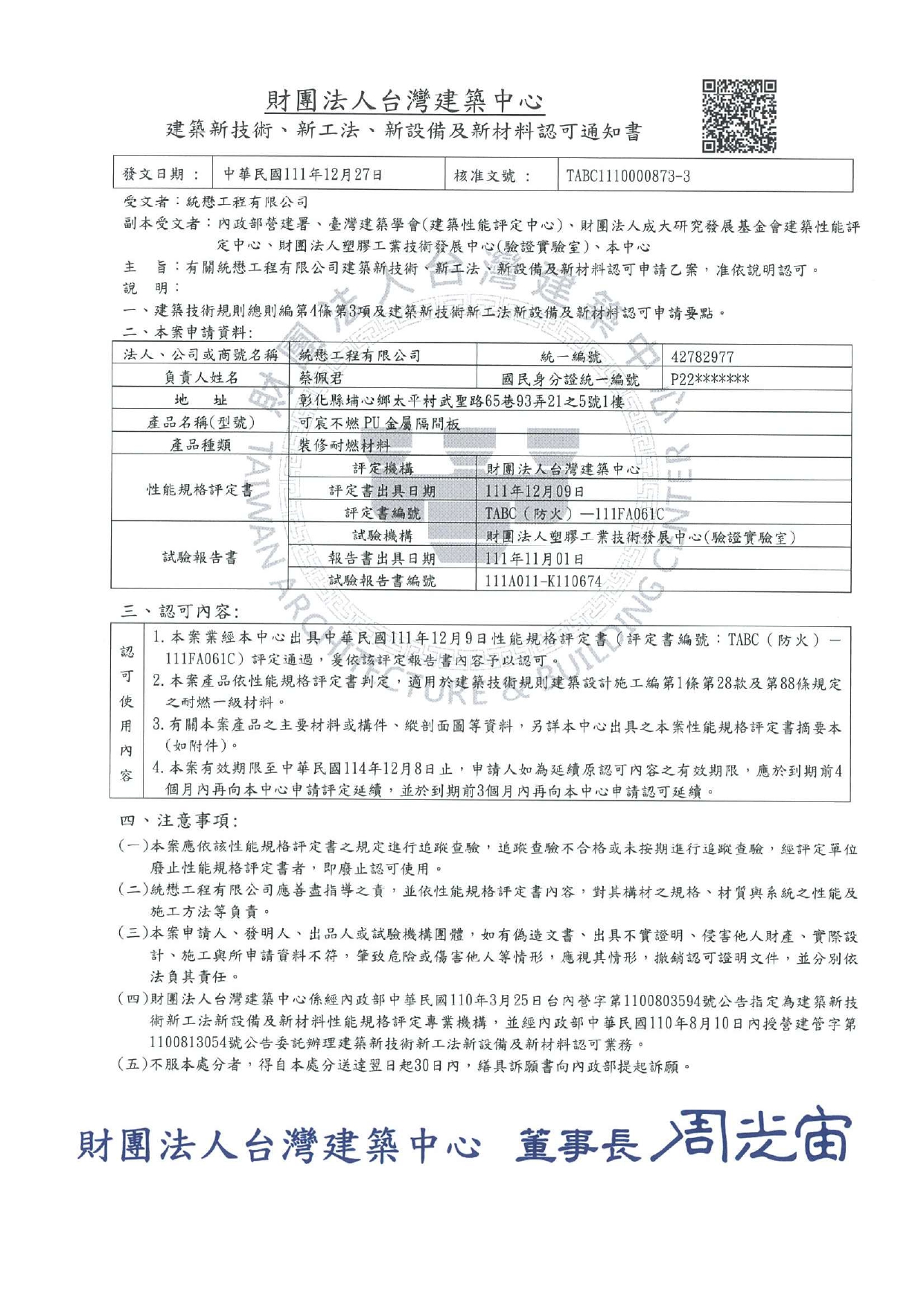

PU foam is another significant technology. Cleanroom PU foam panels are materials produced using polyurethane (PU) foam technology. This material offers excellent thermal insulation, fire resistance, insulation, soundproofing, and a smooth, lightweight surface. Its resistance to moisture and mold makes it a preferred choice for food processing facilities when selecting partition materials. Furthermore, PU foam material exhibits strong environmental performance and provides outstanding durability and long-term utility, making it a prominent choice for future partition needs.

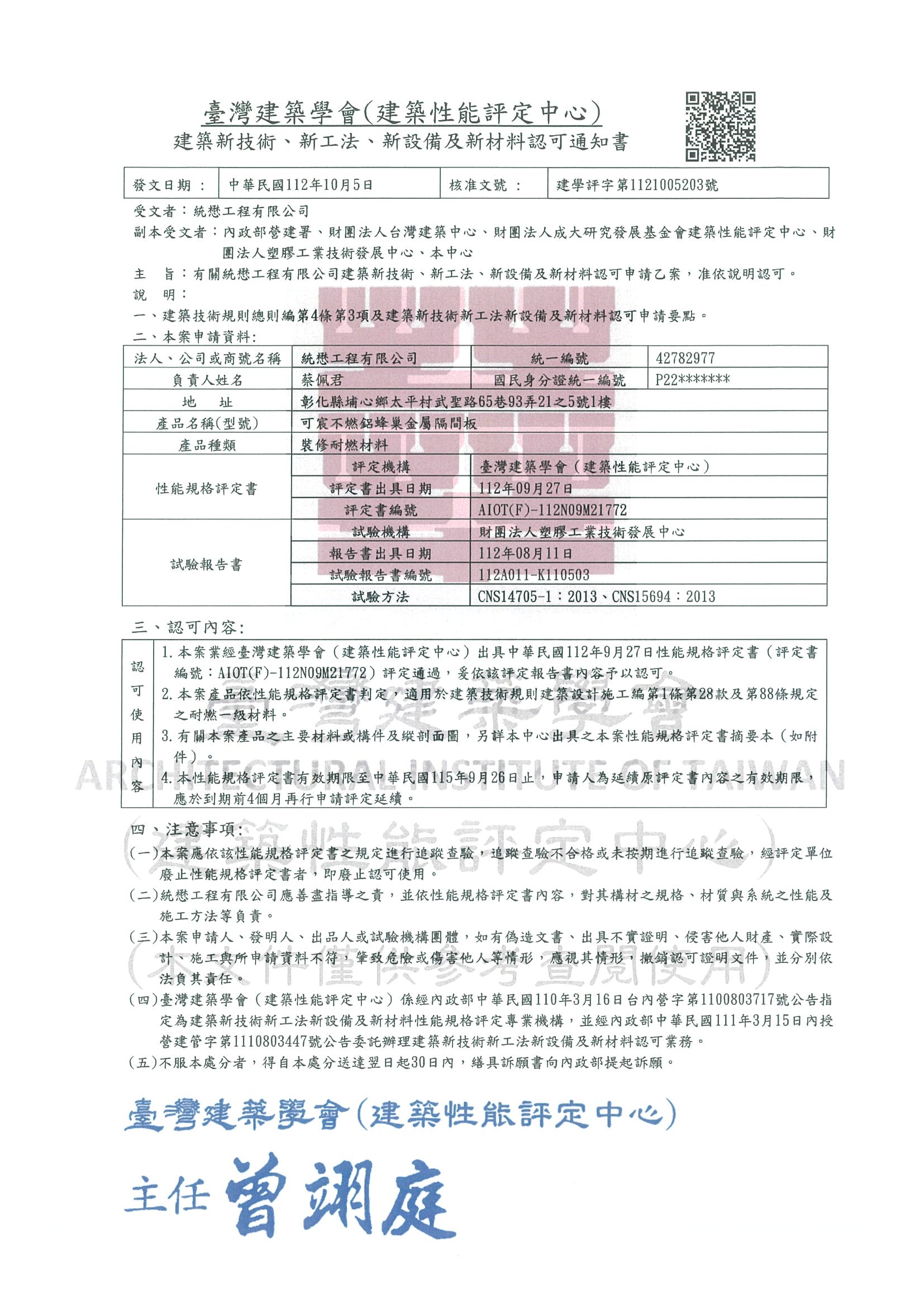

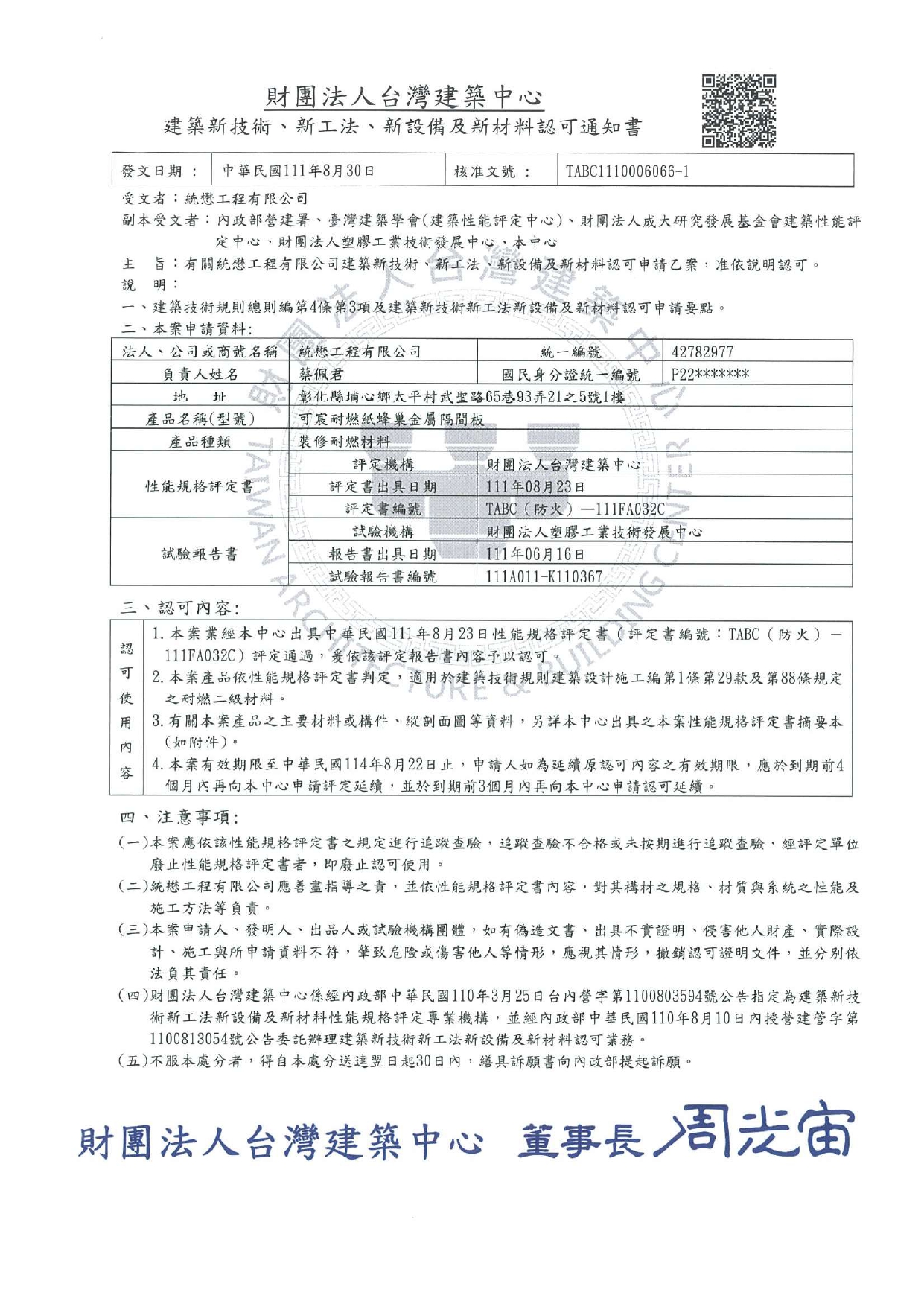

Cleanroom paper honeycomb panels are materials made using a paper honeycomb structure. This material offers excellent rigidity and strength, with a smooth, lightweight surface that's easy to process and install. It also provides good sound absorption, thermal insulation, and insulation properties. It is the most cost-effective option among the three panel types and is commonly used for general applications such as office partitions, suite partitions, and more.